This is a link on how to setup a hurst roll control kit on a cobra.

I have this setup and it works great.

http://www.joelynch.org/cobrasite/Jo...line-lock.html

Installing Line Lock

These notes apply specifically to a 99 Cobra with ABS. A Mustang GT and other new cars, at least through the 2001 model year, are very similar. I have added some notes from people who used the initial version of this page for their install.

You will need the following items and tools....

These can be obtained from either Jeg's or Summit. In addition, you will need the following to duplicate my installation; your needs may vary:

- Hurst Roll Control Kit Part Number 174 5000, Includes the solenoid, pushbutton, light, instructions

- Hurst Roll Control Adapter Fitting Kit Part Number 567 1516, Includes fittings to adapt 3/16" fittings to metric

- Hurst Installation Kit Part Number 567 1510, Includes some tubing, fittings, and plugs, no metric

Some people have commented that the Hurst installation kit has too much stuff left over and that the money would be better spent just buying the needed fittings and the two 12" brake lines and the adapter fittings and save some money. If you want, instead of buying the installation kit and one additional 12" line, buy the following loose pieces AND the adapter fitting kit....

- One Additional 12" long 3/16" brake line

- One 1/4"x 3/4" bolt, nut, flat washer, lock washer

- Velcro adhesive strips--3" total length

- ground lugs

- 4amp in-line fuse

- 16 gauge wire

Tools Needed:

- two 3/16" x 12" brake lines

- two 1/8" pipe thread plugs for the unused ports on the solenoid

- two 1/8" pipe thread male 90 degree angle fittings with 3/16" female inverted flare to connect the tubing to the solenoid ports

I wanted to install the line-lock switch and light where they could be removed and stuffed into the console; I also wanted to avoid drilling more holes than necessary. It was also important to mount the solenoid as close to the ABS module as possible.

- Tape

- Solder

- Soldering iron

- 5/16" drill bit

- 1/4" drill bit

- Electric drill

- The following open-ended wrenches:

- 3/8 inch

- 1/2 inch

- 7/16 inch

- 10 mm

- 12 mm

- 13 mm

- 14 mm

- 10 mm socket

- 6" extension

- Ratchet

- Brake bleeder

- Brake fluid

- The hot wire can be tied into the same connection as the power to the Abbott unit, using a hot wire in the console just to the left of the shifter.

- I used a two-sided Velcro strip, one side on the side of the switch, the other just to the left of the CD player, and installed the switch there.

- In this location, the switch can be operated with your index finger with the shift lever in first gear position.

- The indicator light can be placed on the top of the dash using another small piece of two-sided Velcro.

- The light can be seen staging in either lane.

- The wires are run easily into the console through the top of the shifter boot.

- The hot wire can be run through the air conditioner drain hole in the firewall and routed up on the left side of the engine compartment to the ABS module.

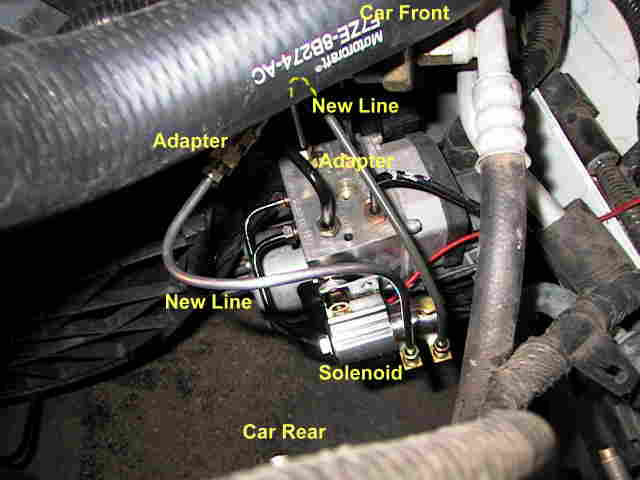

The metric fitting kit is needed to fit the MC1 line going to the ABS unit and to fit the ABS unit MC1 port. The Hurst solenoid uses 3/16" tubing and fittings and the ABS module has 10 mm fittings in it. You have to convert to 10 mm to 3/16" fittings using the union and fittings in the Mustang specific kit. The kit is marked for 96-99 Mustang with ABS and worked perfectly. I used two 12" lines to run from the MC1 tubing union and back to the MC1 port on the ABS module.

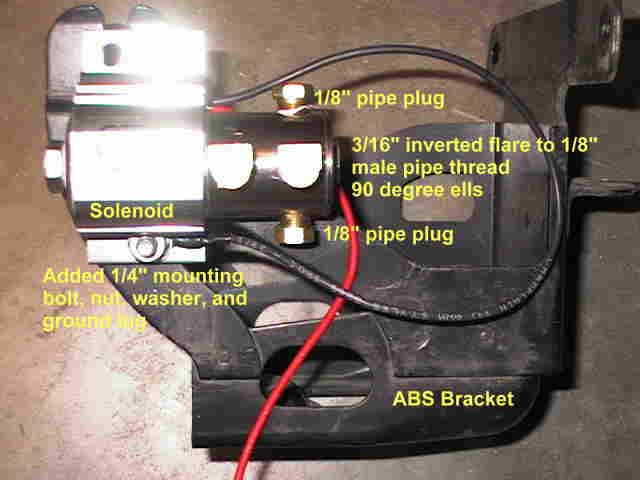

- Mount the solenoid on the rear of the ABS module bracket using the rear mount bolt and adding one bolt.

- Two bolts are needed to hold the solenoid securely.

- Drill one hole in the solenoid mount to 5/16" so that it will fit over the stud.

- Use two 5/16" washers to space it out so that it fits the bracket contour.

- Remove the bracket from the car to drill one 1/4" hole for the lower mounting bolt.

- Reinstall the bracket.

- Mount the solenoid. (The brake lines are in the way if you try to put the bracket back on with the solenoid mounted.)

- Put a ground lug on the solenoid ground wire under the 1/4" solenoid mounting bolt.

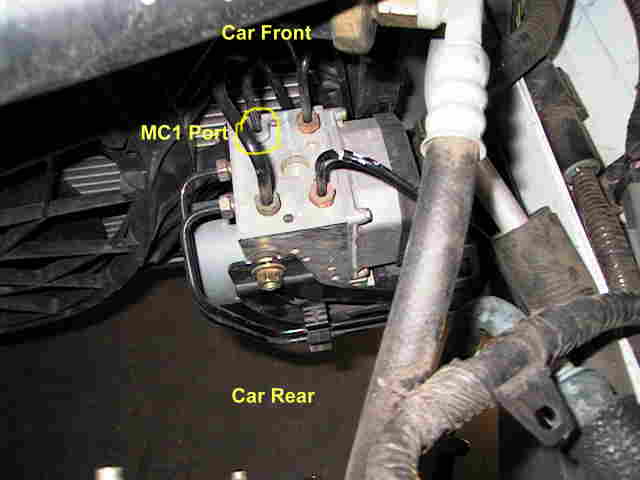

This is what the ABS looks like from the top before the Line-Lock was installed:

Here is the bracket removed from the car and drilled for the solenoid mount:

Here is the finished solenoid installation:

You have to bleed the brakes after installing the line-lock.

How it works:

The line-lock is nothing but a solenoid valve in the front brake lines which is

energized (closes) on pressing the switch near the shifter.

It is used at the line and in the water box. At the line, you can stage, apply the brake,

push the button, let off the brake, and the front brakes are held on until the button is

released. This allows you to let out the clutch some without accidentally rolling the car

forward. Release the button at the same time you release the clutch to launch

the car.

In the water box, you can hold the car in the box using the front brakes only, after

positioning the car, pushing the brake pedal, pushing the switch, release the foot

brake, spin the tires to your heart's content; as you release the button, the car will move out of the

box and lurches as it hits drier pavement. During normal driving, the solenoid is open and the brake pressure is applied to the ABS

unit exactly as it is without the solenoid installed. Only when the solenoid is powered

via the dash button is the brake line valved off and pressure held on the front brakes.

Results 1 to 3 of 3

-

06-20-06, 01:36 PM #1

Hurst Roll Control Line Lock Instructions

-

06-20-06, 01:57 PM #2

how much of a pain in the ass was it to install?

-

06-20-06, 02:04 PM #3Everything is a pain the first time.

Originally Posted by Gene

Originally Posted by Gene

I could probably do it in 2-3 hours now.

If you do this method just get all the parts from Hurst. I spent a day trying to find a few fittings. Of course no one ever has what I need.

Works good at the track.

Reply With Quote

Reply With Quote