I have a Centerforce Dual Friction clutch, fidanza flywheel, Mc Leod TOB, new FRPP TOB, Fiore Firewall adj, Steeda quick release quadrant, etc etc etc

About a month and a half ago I had my TOB replaced along with the TOB retainer sleeve because the TOB was chirping like crazy. Since then I have not put too many miles on the car and the TOB is chirping yet again

I need to get this fixed but have tried everything to relieve the problem and nothing works. I can't see where the TOB rests against the pressure pate due to the weights surrounding the TOB on the PP, my Kook's LT's don't help the problem either. I can loosen the FW adjuster but the chirping doesn't go away, if I release it too far the car won't go into gear of course. I have it adjusted to where there is about 1/8" gap between the fw adj and the black sleeve that surrounds the cable (Which is where I understand it should be when the plastic clutch cable surround is pull away from the silver FW adjuster knob?) and the TOB is still chirping. WHY? It doesn't start until the trans/motors is warmed up, so I would assume there is some sort of expansion that takes place and that causes the TOB to ride on the pp. That's all I can think of other than maybe the cable needing to be replaced, i've seen them snap or fray but mine seems fine. I'm just lost as to what I can do to fix this issue because i'm losing enjoyment in driving the car

Any input in appreciated

Thanks guys,

Josh

Results 1 to 7 of 7

Thread: Throw Out Bearing HELP

-

04-27-08, 03:02 AM #1

Throw Out Bearing HELP

-

04-27-08, 01:07 PM #2

To set correct throwout bearing free-play you must physically look at the TB in relation to the pressure plate fingers. There should be about 1/8"-1/4" gap between the two. Your throwout bearing is making noise because it is spinning all the time. If you loosen the adjuster all the way up and it still chirps more than likely the clutch fork is resting against the transmission housing on the aft side. As your clutch wears the pressure plate fingers move towards the back of the car. In cases of extreme wear the fork will not be able to move back any more due to transmission housing contact. You more than likely need a new clutch.

Sold

2004 Cobra, Whipple ,TH-400

Burning Corn

9.97 - 135.5

-

04-28-08, 11:54 PM #3

Thanks for all the info Jeff

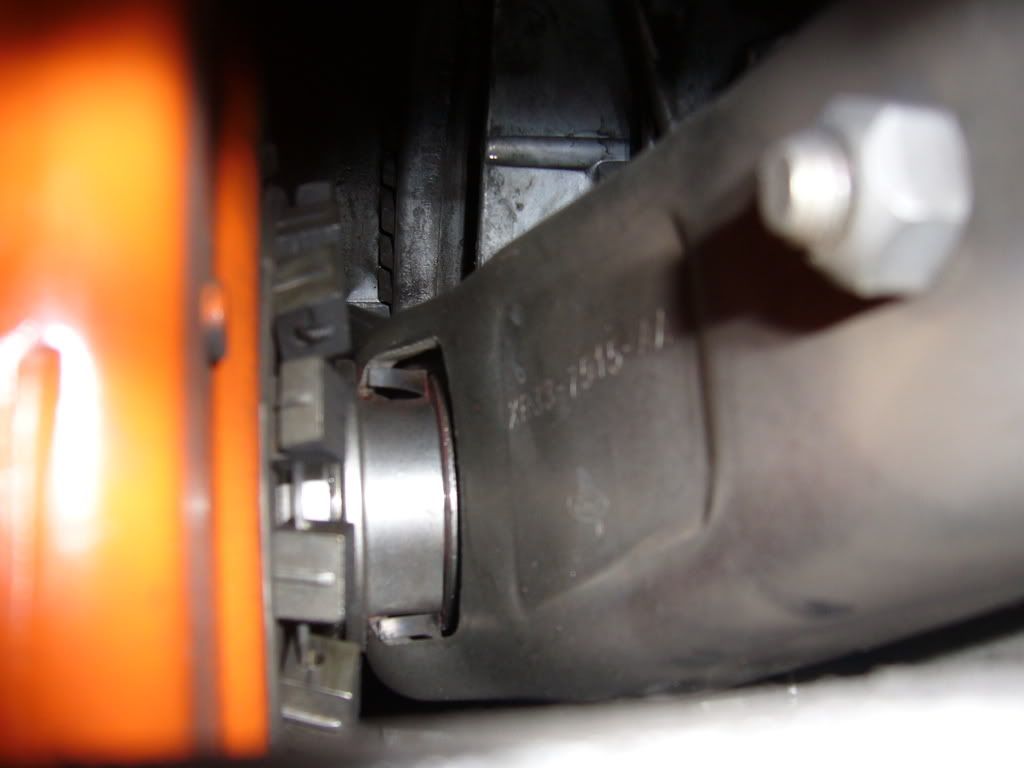

Here are a couple pics:

The weights seem to block the view of the Pressure plate and TOB

-

04-29-08, 12:04 AM #4

The throw out bearing is on the pressure plate for sure. If you can look at it with the car running I am sure it is spinning which causes the irritating chirp.

If the fork can not move back any further I would recommend a new clutch.

You want about 1/8 to 1/4 gap between the TB and the pressure plate. The entire purpose of the LDC spring is to take the deal feel out of the gap.

A correctly set clutch will not have the TB moving when the clutch is engaged.Sold

2004 Cobra, Whipple ,TH-400

Burning Corn

9.97 - 135.5

-

04-29-08, 12:48 AM #5

So what is the reason for those weights on the pressure plate?

The current setup is:

http://www.lightningforceperformance...age-p-335.html

It is the Fidanza billet flywheel with the interchangable friction ring, i'm looking at the Spec 3+ clutch.

Josh

-

04-29-08, 03:43 PM #6

I am not really sure being I have no experience with the DF.

Sold

2004 Cobra, Whipple ,TH-400

Burning Corn

9.97 - 135.5

-

04-29-08, 04:50 PM #7

Specifically what you are looking for is a gap between the arrows.

I have a little bigger gap because I prefer the pedal to engage closer to the floor. I can lessen the gap and have it engage closer to the top of the pedal.

The ultimate goal is to not have the bearing spinning when engaged.

Sold

2004 Cobra, Whipple ,TH-400

Burning Corn

9.97 - 135.5

Reply With Quote

Reply With Quote